Manufacturers must embrace a software-centric approach that streamlines workflows to connect the physical and digital domains. Source | Stock, Copilot

Today, designers and engineers are accustomed to working with digital tools in their day-to-day jobs. Yet, over the last decade, these tools have evolved and unlocked new capabilities and productivity gains, enabling part and mold designs to be more complex and data-driven.

However, a central challenge in manufacturing lies in the scattered nature of data that exists across the product lifecycle. From design and moldmaking to manufacturing and quality control, valuable data is generated in silos, hindering seamless collaboration. Charlie Wood, Ph.D., vice president of innovation, research & development at SyBridge Technologies, believes that the concept of the digital thread has emerged as a solution, envisioning an interconnected flow of data from the inception of an idea to the final product.

“This digital continuum offers a centralized source of truth, facilitating easier tracking of changes, interconnecting production data with design and simulation, and unlocking the potential for creating digital twins and machine learning models,” Dr. Wood says.

The advantage of establishing a digital thread is evident in its ability to pave the way for digital twins and machine learning models. This shift from deterministic to probabilistic models opens avenues for preemptive defect detection and enhanced process simulation.

Design Libraries and Conformal Cooling

To bridge the gap between the physical and digital realms, manufacturing must adopt a software-driven approach that optimizes workflows, according to Dr. Wood. He shares two practical examples that illustrate this transformative journey: digital design libraries for enhanced productivity and additive manufacturing (AM) for improved performance.

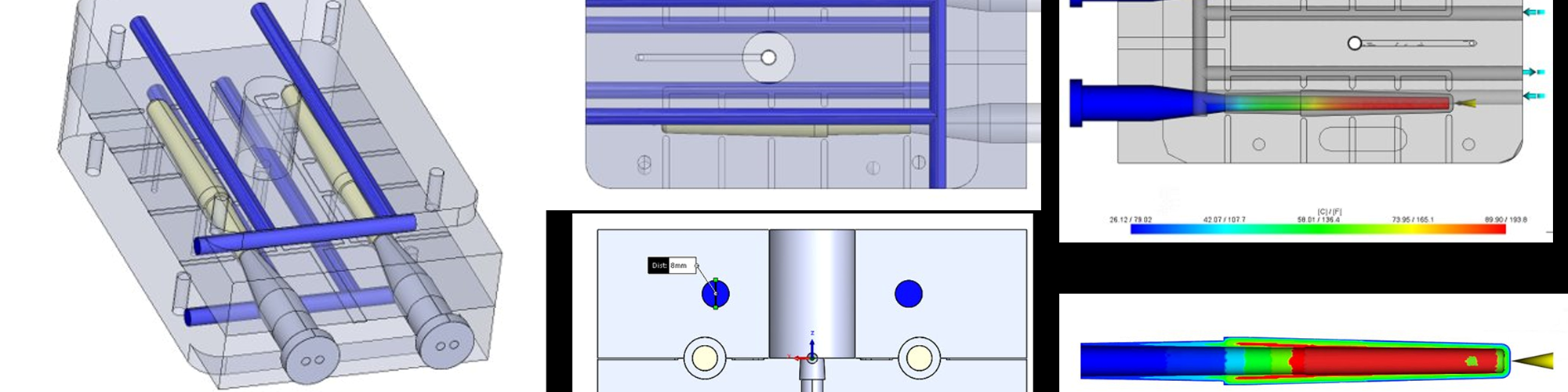

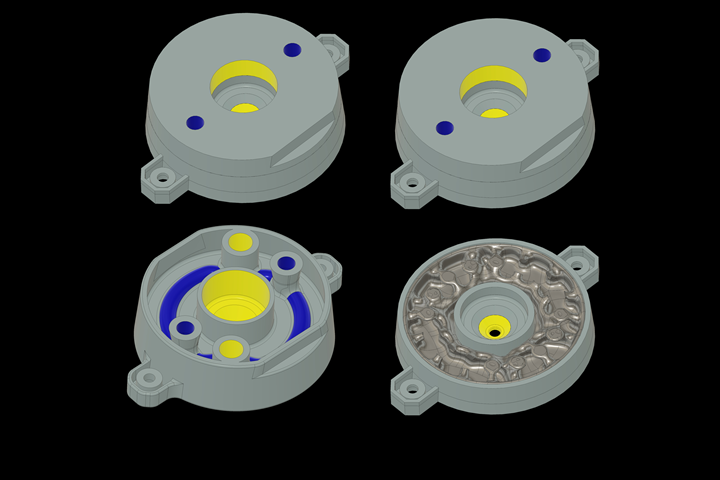

Advancements in computational tools help mold designers identify the most effective cooling designs such as conformal, turbulent, lattice or generative. Source (All Images) | SyBridge Technologies

1. Digital Design Libraries

Designing molds for manufacturing is a complex task that demands precision and efficiency. Digital design libraries offer a solution by introducing parametric design, enabling quick selection and placement of standardized components. This approach reduces the complexity of digital information storage by representing components through rules rather than individual instances.

“This intentional shift toward a software-driven workflow has proven impactful,” Dr. Wood says. “By gradually expanding the coverage of design libraries, teams experience faster design times, smoother onboarding of new designers and a significant reduction in design-related issues. The result is a controlled design environment that enhances overall productivity.”

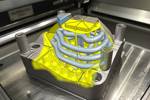

2. Conformal Cooling

The last five years have witnessed advancements in metal AM, opening new doors for moldmaking. For example, transitioning from a successful pilot to scalable production. The focus here is on conformal cooling, a method that significantly improves cycle times (see sidebar). Dr. Wood admits that most new customers look to conformal cooling solutions after they have experienced a problem in a tool build.

“This is a common entry point, as it helps to address issues in problematic tools. However, the more integrated and forward-looking approach is incorporating conformal cooling in new tool designs,” Dr. Wood notes. “This approach allows for a holistic and seamless integration of conformal inserts into the tool, covered by warranties and guarantees while tapping into the combined expertise of molding and AM.”

The process involves two distinct workflows: designing for conformal cooling and the subsequent manufacturing of the part. Mold builders can use advanced mold flow simulations and physical simulation tools to explore and optimize design candidates.

“They can also take advantage of the integration of artificial intelligence and machine learning to iterate through designs, simulate outcomes and explore diverse designs, including turbulent and lattice structures,” Dr. Wood says. Machine learning algorithms leverage massive datasets to uncover design space nuances, leading to performance enhancements that were previously unforeseen.

At the same time, the mold builder can evaluate the manufacturing parameters of metal 3D printing, such as surface roughness and channel sizes. Then, using a structured approach and database methodology, they can determine the optimal orientation for manufacturing.

“When these two workflows converge, the result is a tangible improvement in conformal cooling, reducing cycle times and machine lead times. Aligning these separate data models early in the process accelerates decision-making and ensures a more seamless transition from development to production,” Dr. Wood says.

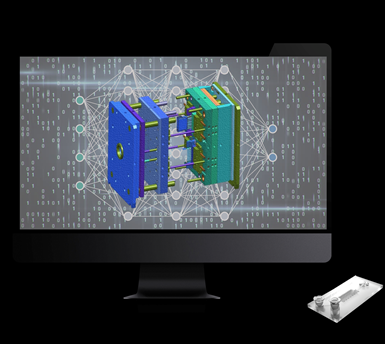

Machine learning helps design engineers in early-stage decision-making identify statistical anomalies in manufacturing and inform design based on machine accuracy Source | SyBridge Technologies

Looking Ahead

Wood sees machine learning continue to evolve as a powerful tool for leveraging the vast amounts of data generated in mold manufacturing. It can help design engineers in early-stage decision-making identify statistical anomalies in manufacturing and inform design based on machine accuracy, such as defect prediction, accurate design for manufacturing and feature-based accuracy assessment.

“The digital thread serves as the foundation for creating a data lake, enabling machine learning algorithms to identify correlations and streamline decision-making processes,” Dr. Wood reiterates.

While the integration of machine learning in manufacturing might seem futuristic, Dr. Wood notes that many companies are already putting these models to use in a variety of ways, ranging from machine health monitoring to on-demand quoting engines. He believes that over time, we will find more use cases and capabilities of machine learning models that will unlock new levels of access and productivity for everyone. For example, there are on-demand manufacturing platforms that use custom manufacturing execution system (MES) software to create a data lake that serves as the foundation for machine learning models.

The challenge lies in establishing robust data infrastructure across the industry, enabling accurate leveraging of machine learning capabilities. Dr. Wood emphasizes that the path forward for mold builders must involve a deliberate and phased approach, starting with critical components and gradually expanding their data models. Last but not least, the workforce involved in this transformation must possess not only software development skills but also a deep understanding of manufacturing logic.

Related Content

How to Select a Mold Temperature Controller

White paper shares how cooling channel analysis, which collects maximum pressure drop, total flow rate and heat dissipation, eases the performance evaluation of mold temperature controllers.

Read MoreThe In's and Out's of Ballbar Calibration

This machine tool diagnostic device allows the detection of errors noticeable only while machine tools are in motion.

Read MoreTips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

Read MoreMoldMaking Technology's Most-Viewed Content 2022: Products

MMT shares the five top-viewed technologies, equipment and services of 2022 in each Engineer, Build, Maintain and Manage tenet based on Google Analytics.

Read MoreRead Next

Growing AM's Presence in Moldmaking

Advanced Michigan mold manufacturer advocates for additive manufacturing in moldmaking through collaboration and education.

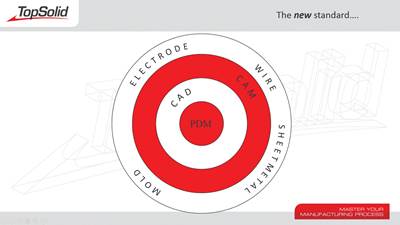

Read MoreManaging all That Data

Product data management may have a bad rap, but making it a priority rather than an afterthought can help make the most of your design and machining information.

Read MoreTransforming Moldmaking into Digital Industrial Manufacturing

Moldmaking and digitalization is at the core of this global industrial manufacturing company’s consolidation and diversification plan.

Read More