Profile

R&D Drives Innovation and Problem-Solving at Michigan Blow Mold Builder

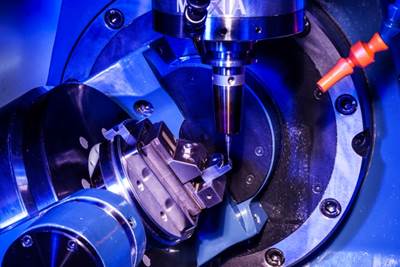

Mid-America Machining focuses on reshaping designs, “right weight" initiatives, continuous improvement and process refinement to enhance moldmaking efficiency.

Christina Fuges

Editorial Director, MoldMaking Technology

Father/Daughter Team Takes Mold Business into the Future

Innovation, personalized service and a team’s collective mold manufacturing experience earn customer loyalty for 56 years and set the business up for future success.

Read MoreBalancing People, Process and Technology for Program Management Success

Using the expertise of its team members and emphasizing efficiency, this Michigan mold builder's process is designed to function as a highly efficient system.

Read MoreA Passion for Innovation in High-Precision, Multi-Cavity Moldmaking

Boucherie uses its dedicated R&D facility to develop new mold, machinery and automation technologies to stay ahead of the competition.

Read MoreNextGen Mold Technologies is Sticking to the Plan

I caught up with Dennis Goggin, president of NextGen Mold Technologies, to learn how much has changed for this startup mold builder since we last connected.

Read MoreCombining Innovation and Artistry to Build Complex, Precision, Multi-Cavity Molds

This Florida mold builder is about high-performance, high-precision moldmaking by blending craftsmanship with technology.

Read MoreOpenness to New Manufacturing Techniques Gives Mayer Tool & Engineering a Competitive Edge

This Michigan mold builder adapts, problem solves, brainstorms and collaborates to exceed customer expectations.

Read MoreInternational Partnership Improves IBM Preform Precision

Hammonton Mold Co. and ADOP France team up to bring injection blow mold preform design and service to the next level.

Christina Fuges

Editorial Director, MoldMaking Technology

High-Technology, Diversified Mold Builder Has Its Eye on Improvement

Commitment, engineering expertise, flexibility, quality and customer service help Wisconsin moldmaker Triangle Tool LLC discover ways to grow and build molds faster.

Read MoreDesign Strategy Tackles Big and Small Complexity Challenges for Southeastern Mold Builder

Delta Mold Inc.’s core values, engineering expertise, five-axis machines and molding capabilities help the team turn a proposal into a manufactured mold or part with custom design, finishing and assembly.

Read MoreSpecialist Automotive Mold Builder Mentors in Work and Life Skills

Southeastern mold builder PFAFF Molds sets the standard in toolmaking for automotive window and vehicle body sealing systems through knowledge-sharing and automation.

Read MoreCross Training, In-House Capabilities and Collaborative Design Move Helm Tool Forward

Cross-training, bringing it all in-house, molding and collaborative design are essential to Helm Tool's success.

Read MorePennsylvania Mold Builder Doubles Footprint, Maintains Quality and Company Values

Quality Mold Inc. doubles its manufacturing footprint but maintains its private company values and structure, delivering quality and fast turnaround from mold design and build through sampling.

Read MoreIndiana Mold Builder Decatur Mold Offers a History of Grit and a Future of Innovation

Decatur Mold Tool and Engineering Inc. serves as a tooling tour guide, helping busy tooling managers reduce uncertainty, lighten workload.

Read MoreGrowth Requires Mold Builder/Molder to Shift Tooling Focus to Maintenance, Repair and Replacement

The results of aligning awareness and acceptance across departments to balance new tooling and quick response needs.

Christina Fuges

Editorial Director, MoldMaking Technology

Next-Generation Thinkers Redefine Moldmaking Quality and Service

Canada-based NextGen Mold Technologies is a new mold shop using excitement and empowerment to encourage better ideas every day.

Read MoreMold Builder Uses Counter-Intuitive Approach for Mold Challenges

Matrix Tool Inc. answers customers’ hard questions with creative solutions for cavity spacing, tool sizing, runner layout and melt delivery that reveal the benefits of running in a smaller press size at lower cavitation but higher yield.

Read MoreMidgard Inc. Tackles Tooling Challenges and Automates Production to Keep Molds Running

This Eastern Pennsylvania molder does cavity changes daily, making its in-house toolroom critical to quickly fixing mold problems.

Read MoreSmall, Agile Mold Builder Keeps Speed and Accuracy at the Forefront

Michigan-based Zero Tolerance tests the limits of moldmaking and molding with teamwork and technology that permits changes on the fly.

Read MoreNon-profit Organization Advances Diversity and Inclusion Initiatives in Manufacturing to Fill Skills Gap

Build A Dream delivers programs to inspire young women, providing confidence and filling the skills gap by collaborating with speakers, community leaders and businesses.

Read MoreBringing Market-Specific Engineering Experience to Every Project

Experience, acumen and attention to detail help Prodigy Mold & Tool create value and build long-lasting customer relationships.

Read MoreNorth Carolina Mold Builder Works With Purpose and Partnership

Adapting and innovating amidst a change in ownership, doubling sales and maintaining the workforce reflects team resilience and expertise.

Christina Fuges

Editorial Director, MoldMaking Technology

PlastiVan Advocates Early for Careers in Plastics and Moldmaking

The mission of PlastiVan, a national STEM educational outreach program, is to change the perception of plastics one classroom at a time and promote careers in plastics.

Read MoreTaking a Holistic Approach to Training Is Filling a Local Skills Gap

Success coaches through JEVS Human Services’ Tri-State Apprenticeship Program (JTAP) provide guidance and a different way of learning for the whole person for small- to mid-sized manufacturers.

Read MoreLocal Moldmaking Expertise with Global Competitiveness Takes on Tooling Innovation and Training

From quick-change solutions and world mold systems to offshore tooling consulting and project management and apprentice training, this Pennsylvania mold builder continues to advance.

Read MoreCurrent Technology and Trends in a Micro Molding Tooling Center

Contract manufacturer of medical micro components and finished devices discusses current trends and challenges with micro molds—micro milling, cutting tools, mold coatings, CAD/CAM, micro welding, mold design, micro molding, validation, automated assembly and training.

Read MoreTop Grade Molds Is All About Innovation and Collaboration

Top Grade Molds develops technology solutions with a heavy emphasis on R&D, recyclable material trends and collaboration.

Read MoreMidwestern Advanced Manufacturing Design Technology Program Presents Unlimited Career Possibilities

Advanced Manufacturing Design Technology program at Central Community College offers new facility expansion and 100 years of instructor experience to mentor students from drafting, manual machines and CNC to part, mold and die design and advanced machining.

Read More