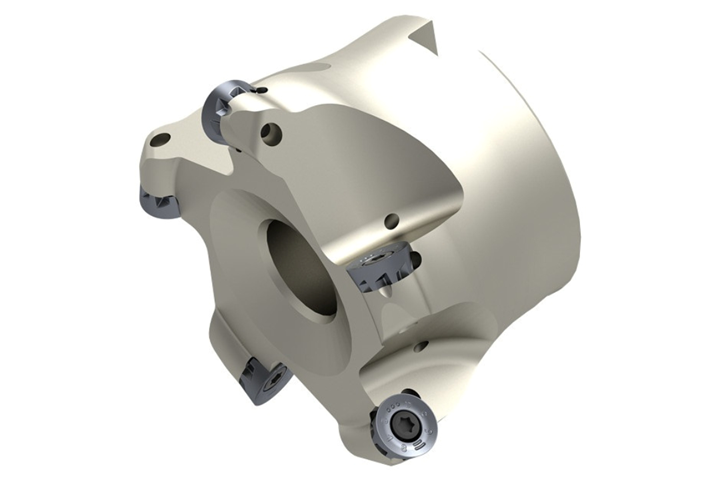

Shell Mill Supports Variety of Rough Milling Strategies

The Ceratizit MaxiMill 251 is optimal for pocketing, mold and die roughing, face milling, slotting and helical interpolation of holes.

The MaxiMill 251, presented by Ceratizit is a shell mill, also known as a button cutter, that offers various rough milling strategies. Utilizing a stable round insert, the positive mounting position provides a soft cutting action, giving lower cutting forces for a smooth cut.

MaxiMill 251 features six face-mounted inserts, with a 2" cutting diameter (max is 2.5") and a 0.24" maximum depth of cut. Applied in a variety of applications, the MaxiMill 251 can be used for pocketing, mold and die roughing, face milling, slotting and helical interpolation of holes. It is also commonly used in aerospace and energy sectors, as it works well in high-temperature alloys, steel and stainless steel. In addition, the MaxiMill 251 is an optimal cutting solution for unstable pieces, older and lighter machines that cannot achieve the performance needed of high-feed cutters, as well as multi-axis machining.

Related Content

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

-

Considerations for Mold Base Material Selection

Choosing the right material can greatly affect the profitability and cost of your application.