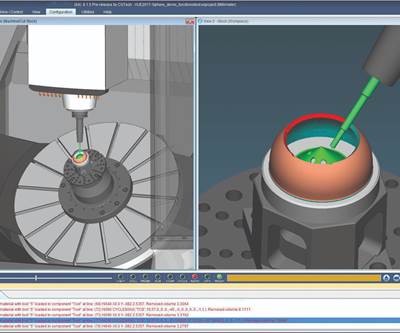

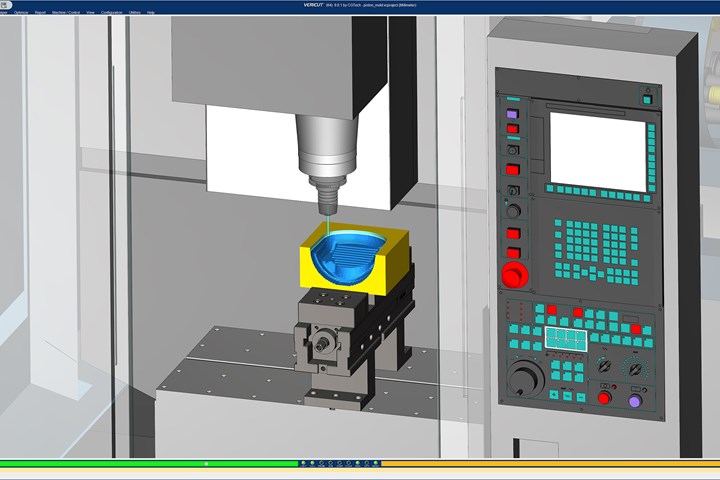

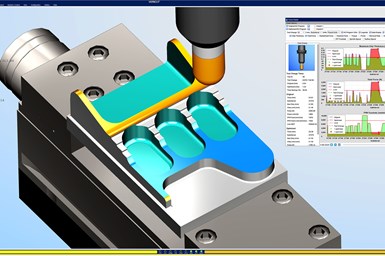

Using a digital twin to validate the machining process saves time and reduces risk, especially with highly complex parts like those made in mold shops. Photo credit: CGTech.

Of all the various manufacturing sectors, plastic injection moldmaking is among the most challenging. The materials are typically tough, the geometries quite complex, the tolerances exceedingly tight. With finished multi-cavity molds often selling for tens or even hundreds of thousands of dollars, the stakes are enormously high, which is why companies competing in this arena require the very best in people, software, tooling and machinery.

No one knows this better than the people at iMFLUX Inc., a Hamilton, Ohio-based mold design, manufacturing and technology firm and a wholly-owned subsidiary of multinational consumer goods giant Procter & Gamble. Through years of intensive effort, the team there has not only developed a proprietary process control technology that significantly improves the results of injection molding operations but has built a highly capable, largely automated moldmaking facility besides.

Always on the hunt for greater manufacturing efficiency, iMFLUX recently evaluated a new technology to increase the shop's metal removal capabilities. This wasn't some high-tech automation system or quick-change workholding platform (they already have all that), but rather a software module that reportedly slashes cycle times by up to 50% or more while simultaneously increasing tool life and part quality. Its name? Force Optimization from CGTech of Irvine, California, developer of Vericut toolpath simulation, verification and optimization software.

All Tooled Up

The iMFLUX shop floor boasts impressive CNC equipment. The shop’s prototyping and low-volume side is home to OKK (Glendale Heights, Illinois) and Hurco (Indianapolis, Indiana) machining centers, most with four or five-axis capabilities. The EDM department houses Makino (Mason, Ohio) wires and sinkers, the largest with nearly 20 inches of Z-axis travel. Automated coordinate measuring machines (CMMs) and vision systems from Hexagon (North Kingsroad, Rhode Island) and Micro-Vu (Windsor, California) are located in strategic locations. All equipment is arranged in cellular configurations for the greatest efficiency.

The manufacturing floor at iMFLUX is home to CNC machine tools from Hurco, OKK, Makino and other high-end equipment. Photo Credit: iMFLUX.

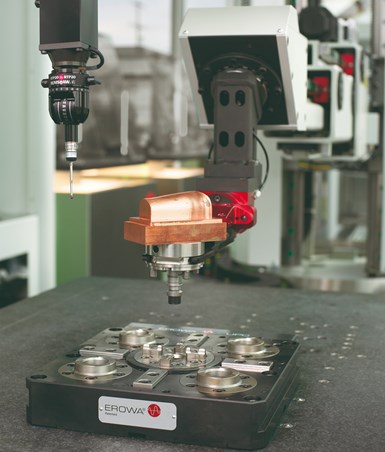

The heart of the iMFLUX production area is its automation line, filled with 20,000 and 30,000-rpm Makino V33i five-axis machining centers, dual wash stations, an automated CMM and serviced by an Erowa (Arlington Heights, Illinois) linear robot and cell controller. “The system carries up to 700 workpieces mounted on zero-point pallets that can be transferred to any of the stations,” says continuous improvement and education leader Erik Morgan. “And two of the Makinos are graphite only, responsible for machining 6,000 to 7,000 electrodes each year.”

Automated inspection is a key part of iMFLUX’s lights-out machining strategy. Photo Credit: Erowa

Moldmaking takes more than good equipment, however. Programmer Jonathon Edwards points to the one thing that separates iMFLUX from other moldmaking shops—its people. “I’ve worked in a lot of shops over the years, and this is the only one where I've seen each machinist with their own computer and a full seat of programming software,” he says. “Granted, we do control what can be programmed and by whom, but because we’re a nearly paperless shop and all of our information comes from the CAM system, it's important that everyone has access.”

In all but one instance, the Force-optimized tool edges showed far less wear, with none of the chipping associated with the non-optimized toolpaths.

What's Old Is New Again

Another thing they have access to is Vericut. Five years ago, iMFLUX invested in the well-known toolpath simulation and optimization software, but due to time constraints related to the company's spin-off from Procter & Gamble and subsequent rapid growth, Vericut was admittedly not implemented as it should have been. Advanced manufacturing engineer Gary Bare explains that all changed in early 2020 when he and others agreed that simulation should play a key role in their machining processes in the future. They reevaluated the original purchasing decision and once again decided in favor of Vericut.

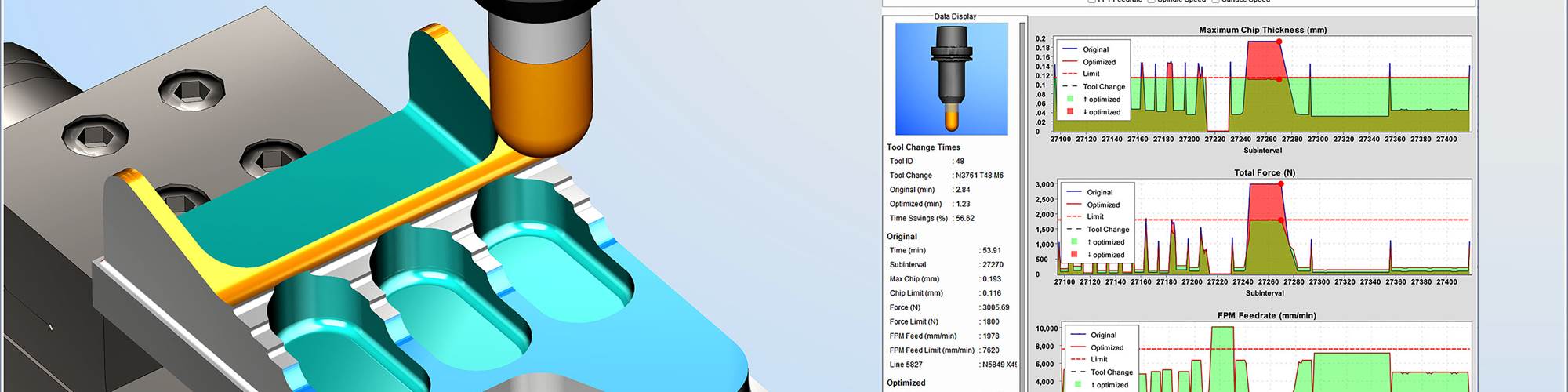

Force Optimization from CGTech has reduced machining cycle times by at least 17% at iMFLUX—and in some cases up to 45% or more—thus generating an ROI of just 1.4 months. Photo Credit: CG Tech

One factor that played heavily in that decision was CGTech’s recent development of Vericut Force. This physics-based NC program optimization software module analyzes and optimizes cutting conditions throughout NC program operations. This module promises significant opportunities for cycle time reduction and enhanced tool life. Edwards and the rest of the manufacturing leadership group then made another decision—to see if the software developer’s bold claims held water. Using the same scientific approach applied to the rest of the company’s activities, they set aside the necessary time and resources to put Force to the test.

Pedal to the Metal

The team made nine separate machining tests, evaluating each cycle time, cutting tool life and temperatures at the tool and workpiece. Trochoidal milling and radial chip thinning strategies were used throughout, with tests performed on various Hurco, OKK and Makino equipment models. Notable results include:

During one hard milling operation, the machinist noted that Force optimization provided “the best sounding roughing cut I’ve heard in our shop.” Photo Credit: iMFLUX.

- While machining a 420 stainless steel workpiece heat-treated to 48 Rc, Force reduced cycle time from 7:51 to 4:55, a 37% improvement. The machinist used the word “awesome” to describe the Force toolpath.

- On another workpiece made of the same material, cycle time fell more than two hours, saving the company $1,366 on a single multi-piece order.

- Several parts with relatively simple toolpaths or large numbers of drill holes generated savings between 9.7% and 19.9%. Random inspections of the chips showed them to be “amazingly consistent.”

- When hard milling complex surfaces in 52 Rc Stavax, a type of mold steel, Force cut cycle times by 51%. The machinist said it was “the best sounding roughing cut I've heard in our shop.”

- Machining of a P20 test piece produced a 30% reduction. The programmer noted that Force would “save us a ton of time and money on tools and machine intervention.”

- Force was also applied to a previously optimized program. Doing so not only lopped one hour off a six-hour cycle time but caught and removed a tool loading spike that would almost certainly have broken the cutter.

In each case, operators inspected the cutting tools afterward under 72x magnification. In all but one instance, the Force-optimized tool edges showed far less wear, with none of the chipping associated with the non-optimized toolpaths. In one test where a failure did occur, it was determined that a previous machining operation had caused work hardening, causing one of the edges on the four-flute end mill to chip—on the tool without Force Optimization, all four flutes were damaged.

iMFLUX Inc has developed a proprietary process control technology that significantly improves the results of injection molding operations. Photo Credit: iMFLUX.

Aside from more consistent loading of the cutting tool and elimination of the spikes that often lead to failure, Force also reduced heat generation. By measuring with an infrared thermometer, the iMFLUX team saw that the test parts—which were cut dry—never exceeded 90°F (32°C), and the cutting tools stayed below 180°F (82°C), an ideal temperature. In comparison, the parts cut with non-Force toolpaths routinely hit 300°F (149°C), most likely creating the work hardening mentioned earlier. Cooler cutting conditions also mean less heat in the workpiece and machine tool, which are both important contributors to part accuracy.

Aside from more consistent loading of the cutting tool and elimination of the spikes that often lead to failure, Force also reduced heat generation.

Looking Back

Bare summarizes the test results like this: “Vericut’s Force module saved at least 17% on even the most basic part geometries. On those considered more complex, reductions of up to 45% were typical.” As noted, Force also improved tool life significantly, with little to no chipping or edge wear, while the lower cutting temperatures reduced thermal growth. Lastly, Force Optimization’s more stable processes tended to improve machinist and operator confidence. iMFLUX estimates that its Vericut return on investment was only 1.4 months and that not using Force Optimization would cost the company $21,000 monthly.

“We looked at many alternatives, and I’m very glad that we stayed with Vericut, especially given what we’ve seen with Force Optimization,” says Bare. “We put everything on the table, checked the boxes on what worked and what didn’t and then narrowed it from there. Unfortunately, we lost time on the initial implementation, but it’s a good thing we put Vericut back in the equation. It was the right choice for us.”

Related Content

MoldMaking Technology's Most-Viewed Content 2022: Products

MMT shares the five top-viewed technologies, equipment and services of 2022 in each Engineer, Build, Maintain and Manage tenet based on Google Analytics.

Read MoreTips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

Read MoreLeading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

Read MoreIt Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read MoreRead Next

Accurate Additive Manufacturing Requires Machine Simulation

Machine simulation can help to provide a clear picture of the additive manufacturing process from the first to the last step.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More