Highly Wear-Resistant Thread Milling Grade Promotes Difficult Material Cutting

The Walter USA Tiger·tec Gold grade WSM37G is most effective for machining blind-hole and through-hole threads in hard steel, stainless steel, cast iron and heat-resistant super alloys.

Tiger·tec Gold WSM37G from Walter USA is a wear-resistant thread milling grade with a physical vapor deposition (PVD) aluminum oxide (Al2O3) coating technology. The multiple-layer coating features a titanium aluminum nitride (TiAlN) coating on the carbide substrate for a high level of wear resistance, followed by Al2O3 coating for high temperature resistance and topped with zirconium nitride (ZrN) for optimized friction reduction wear detection.

Thread milling are necessary when it comes to cutting threads into a part or workpiece like a mold, particularly if it’s made of a difficult-to-cut material. For example, indexable inserts made of Walter’s WSM37G universal grade are effective for machining blind-hole and through-hole threads in steel, stainless steel, cast iron, heat-resistant super alloys and steel with a hardness up to 55 HRC (ISO P, M, K, S and H material groups). WSM37G inserts are for milling threads with a nominal diameter from UNC ¾ or 16 mm with a pitch range from 3-18 threads per inch (TPI) or 1.5-10 mm.

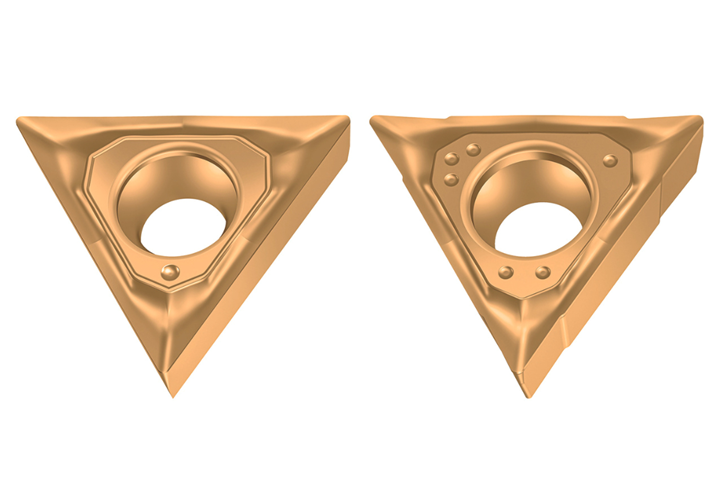

Tiger·tec Gold grade WSM37G inserts are offered in two geometries with a positive basic shape and each with three cutting edges. Both have a smooth, low-friction rake face and defined corner radii for producing threads in accordance with many international standards. The D67 universal geometry is for achieving maximum tool life. The D61 geometry with anti-vibration land is for thread milling with a high level of operational smoothness when using large projection lengths or under difficult machining conditions. Walter developed these chip breakers with grade WSM37G specially for thread milling.

Potential benefits of the Tiger·tec Gold grade WSM37G inserts include process reliability because of the balance between wear resistance and toughness, high productivity due to optimal cutting parameters and universal application even under difficult thread milling conditions. All Walter T2710 to T2713 thread milling cutters accept the grade WSM37G indexable inserts.

Related Content

-

Advantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

-

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.