INCOE Corporation designs and manufactures hot runner systems driven by performance for the processing of all injection moldable plastic materials. INCOE is a global company that is 100% family owned and operated with a commitment to supporting the plastics industry, innovating new products and providing top-level customer service.

An experienced team of professionals in over 45 countries remains committed to quality, partnership and bringing application-specific expertise to the customer. According to the company, its original patented design was the first commercial hot runner nozzle available.

A recent conversation with INCOE’s New Business Development Manager Jim Bott and Business Development Manager David Shirley reveals the answers the following questions:

- Incoe offers a variety of technology, which MoldMaking Technology has covered over the years, here we focus on valve gating technology. What is a common challenge you see with customers today for which valve gate pin control technology is the answer?

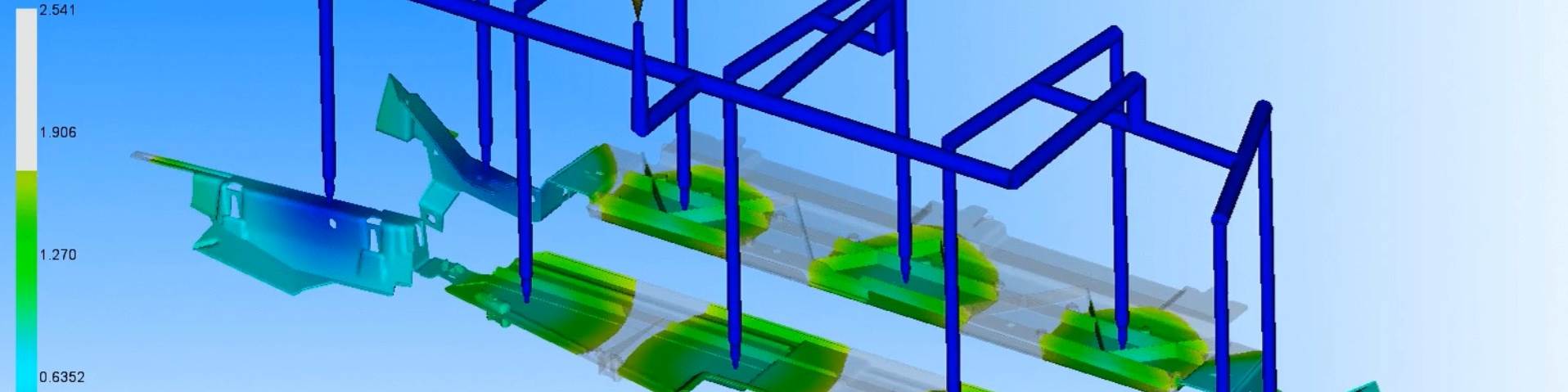

- Let’s move to balanced hot runner systems. I know you partnered with John Beaumont to develop a solution for mold-filling imbalances and cavity-to-cavity variations, can you talk about this scientifically engineered hot runner system, how it’s engineered on a custom basis, what common practice it replaces and how it works?

- Incoe says it ‘partners’ with mold builders to develop the right melt management technology, can you explain what that partnership looks like?

- Can you give me an example of when that helped to develop a specific technology solution?

For more video content from MMT, visit https://www.moldmakingtechnology.com/videos

Related Content

-

MMT Chats: Apprenticeship Program Thrives by Offering Supportive Services and Success Coaches

MoldMaking Technology Editorial Director Christina Fuges invites team members of the JEVS Tri-State Apprenticeship Program (JTAP) to break down how their holistic approach to apprentice training works and what makes it different from other apprenticeship models. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

-

MMT Ask the Expert: Hot Runner Benefits and the Fundamentals of Maintenance and Refurbishment

In this next portion of our “Ask the Expert” series, Husky’s Derrick Hennebicque answers some FAQs about the advantages of hot runner systems and refurbishment strategies. This episode is brought to you by Husky, Melt to Mold Precision.

-

MMT Chats: Developing a Mold Engineering Apprenticeship Model

New mold design and 3D printing company wanted to partner with a local high school to train mold designers and a National Tooling & Machining Association Mold Design Group Apprenticeship was the answer. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.