We live in unprecedented times, where as leaders, we need to find creative ways to maintain profitability and stability for our companies. Because of the current market conditions, capital spending has been reduced, and adding additional staff can be risky for both the company and the new staff member. As a result, companies are forced to find unique ways to increase efficiency.

In the spring of 2019, our team—a 28-man internal mold shop of Ernie Green Industries (EGI)—faced the considerable challenge of building 63 molds in less than one year, which required extensive, high-precision wire EDM machining. The primary focus of the team is precision medical molds for non-evasive surgical devices, and many of our wired inserts and wired holes are very small (0.015 inch x 0.040 inch x 0.500 inch) or have thin steel conditions of less than 0.010 inch. However, in our current state, the shop did not have the wire EDM time needed with its two GF Progressive VP2 machines.

During the quoting phase of the project, we laid out a timeline to see if the project was feasible and quickly found out we did not have enough wire EDM hours. Our average cut time was 126 hours per week or 6,300 hours per year. To accomplish this task, the team needed to react quickly.

The initial solution was what most shops do—buy two additional machines at the cost of $325 thousand per machine and hire the two to three additional staff required to run the new equipment. However, EGI’s consulting partner, Harbour Results, challenged the organization to find another way to accomplish the task without investing in machines or staff.

What we have learned through this assignment is that a company should collaborate with its equipment suppliers to maximize its existing machines and to review all your processes to determine where efficiency improvements can be found, and invest in the training.

Identifying Two EDM Problems to Solve

The team started by looking at how to improve our current efficiency rate. Utilizing two machines, EGI had 38 hours available cut time at 80% efficiency; however, it was only achieving an average of 21 hours cut time per day, or 52% efficiency.

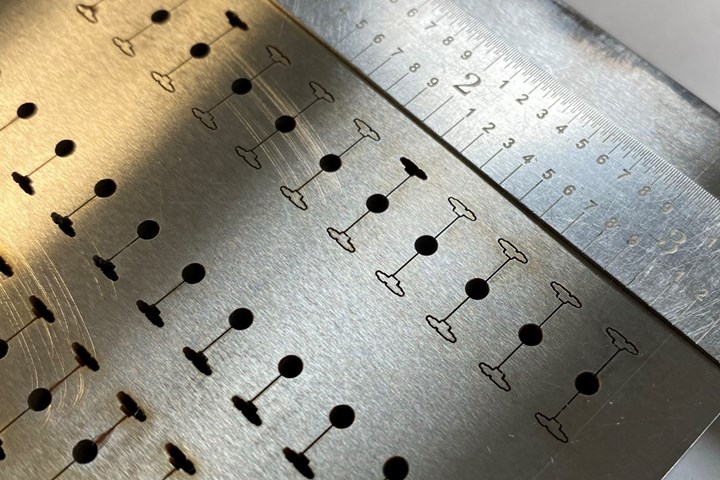

The first opportunity for improvement was to put multiple blocks in the machine. Our toolmaker had always put one block in the machine at one time in the same spot. He was trained to do it this way, 20 years ago. However, if we put multiple blocks in the machine, we could run for extended periods, including over the weekend.

Wire block for small mold inserts.

This leads us to our second issue of dropping inserts/slugs. Some shops will let the insert/slugs fall into the tank, but our inserts/slugs are so small, we could lose them in the tank, or if they got into the machine head, the insert could cause costly machine damage. The toolmaker still needed to catch each insert/slug that dropped. Initially, we decided to run our machines for extended periods, and then on the day shift, go back and drop each insert by hand. Doing so still took 5-10 minutes per insert, and there were thousands of inserts to wire EDM. Implementing these two steps improved cut-time efficiency to 75%, but the team knew there had to be another way to drop the inserts/slugs to increase efficiency further.

Challenging the team to look outside the norm, asking for support from our machine tool supplier and conducting more training on how to use our wire EDM and CAM system, EGI profitably completed the project requiring 63 high-precision molds and is considering additional wire EDM work because of open capacity.

Through research on our machine and learning how others in the industry dropped their inserts/slugs, we found a solution where the wire would weld the inserts back in place after passing the wire tab. This would work, but require new equipment, which was not an option for this project.

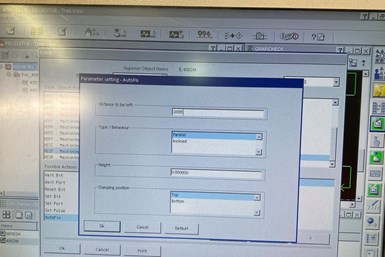

Then, when one of the EDM machines went down, the team reached out for support and, at the same time, asked the manufacturer how they recommended dropping slugs and inserts. The machine has a function, called Autofix, which goes back to each wire tab and reduces it so that the insert can be tapped out with a small punch after the block was removed from the machine. With additional support, we implemented this functionality within one day.

Autofix function goes back to each wire tab and reduces it so that the insert can be tapped out with a small punch after the block was removed from the machine.

Using both the Autofix and running multiple blocks allowed us to achieve an efficiency of 90% or more and significantly increased available capacity. Additionally, the team discovered that EGI’s PEPS CAM system has a similar function to Autofix, which provides the company with multiple ways to achieve efficiency for wiring small, high-precision inserts and pockets.

Seeking Alternative Solutions

So, why did we not know about this function? First, the team was not challenged to look outside their typical solution set of adding equipment and people. Second, the appropriate level of training for the equipment was not required. Lastly, the toolmaker was not adequately trained in the use of the CAM system.

Discovering an Autofix function on one of EGI’s EDM machines and running multiple blocks helped the shop achieve 90% efficiency and increased available capacity.

Challenging the team to look outside the norm, asking for support from our machine tool supplier and conducting more training on how to use our wire EDM and CAM system, EGI profitably completed the project requiring 63 high-precision molds and is considering additional wire EDM work because of open capacity.

What we have learned through this assignment is that a company should collaborate with its equipment suppliers to maximize its existing machines, to review all your processes to determine where efficiency improvements can be found, and invest in the training. Companies should not wait until there is a challenge or an issue but do this proactively to improve capacity and profitability.

Related Content

Tackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

Read MoreUnique Mold Design Apprenticeship Using Untapped Resources

To help fill his mold design skills gap, Jeff Mertz of Anova Innovations, is focused on high schools and underprivileged school districts, a school that has lower graduation and college entrance rates. The goal is a student-run enterprise.

Read MoreWomen Impacting Moldmaking

Honoring female makers, innovators and leaders who are influencing our industry's future.

Read MoreMMT Chats: Marketing’s Impact on Mold Manufacturing

Kelly Kasner, Director of Sales and Marketing for Michiana Global Mold (MGM) talks about the benefits her marketing and advertising, MGM’s China partnership and the next-generation skills gap. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreRead Next

How to Become a Better-Informed Mold Purchaser

Six questions every purchasing manager must answer to improve his or her buying skills and create more value for the company.

Read More2020-2023 Editorial Advisory Board: Meet New Board Member James Jergens

The 2020-2023 version of MoldMaking Technology's EAB features a new crew of 12 industry professionals. Here's one of them.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More