Gate Cutting Technology Advances Mold Material Separation

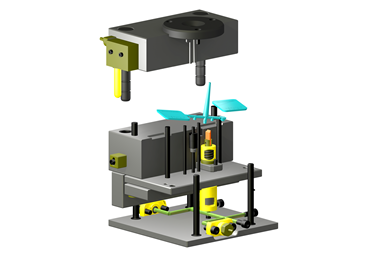

Ermanno Balzi’s latest technology uses the the axial movement of a cutter to optimally separate the molded part from the cold runner during the mold cycle.

Gate cutting technology from Ermanno Balzi enables separation of the molded part from the cold runner during the mold cycle. This is performed via the axial movement of a cutter, driven by a mini cylinder fed with high-pressure oil. The cut is made with the mold closed at the end of the holding phase while the polymeric material is still hot.

According to the company, it should be noted that while the term “cut” is used here, the operation is not necessarily a real cut, but a movement of melted material.

High pressure and accurate time control are required to perform the cut. The company provides two alternative options to control the process. One is the GCM-OIL, a peripherical hydraulic unit able to provide high pressure and communicate with the IMM to control the process. The other is GCM-PMB, a compact pressure multiplier that can be fixed to the mold. The IMM controls the cutting process feeding the GCM-PMB with oil at the right timing.

The gate cutting technology brings many advantages in the production process. It avoids secondary operations that can increase cycle time and doesn’t require expensive cutting jigs. Increased quality of the cut and of injected part promotes process repeatability. It is said to guarantee an optimal cut even with material such as PMMA, which is critical to cut once solidified. It also reduces risks for operators related to cold runner cutting with blunt tools.

The dimensions and shape of the cutter are customized according to each specific project, and can be determined by Ermanno Balzi’s design team. Applications with many types of materials and gates are possible.

Related Content

-

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

-

Fundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

-

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.