Fast Wire EDM Targets 3D-Printed Mold Component Removal

EDM Network introduces the EDMMax 434W that enables customers to economically cut 3D-printed mold inserts from their build plates.

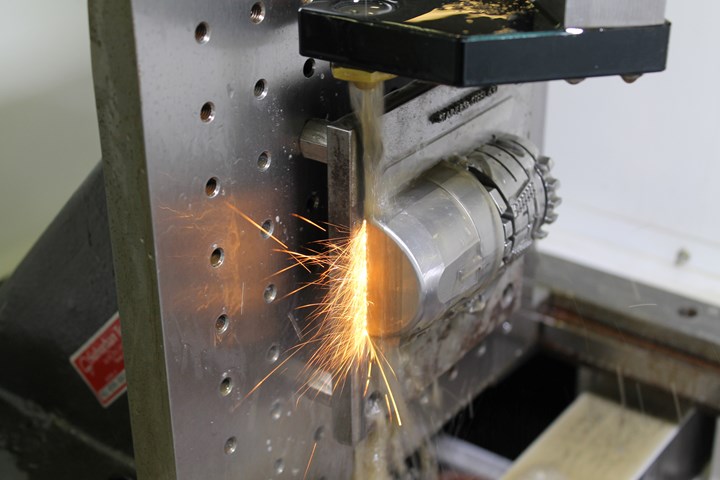

EDM Network Inc. is now offering an economical fast wire EDM solution with the EDMMax 434W for 3D-printed metal removal on parts like the mold inserts above, printed on the Matsuura Lumex Hybrid metal 3D printer/hard mill.

Among other applications, the EDMMax 434W enables companies like Matsuura to optimally cut 3D-printed mold inserts from their build plates. The fast wire EDM has a build plate size of 400 × 400 mm and includes four-axis cutting capability that enables it to cut 3D support structures or other shop-related parts; it uses a “reusable” 0.007'' diameter molybdenum high tensile wire.

Other EDMMax 434W features includes an on-board CAD system, or users can import programs via a USB port or LAN system. Three Pass Cutting technology is included for improved surface finishes and part accuracy.

This fast wire EDM solution is available in eight models including both vertical and horizontal cutting; most models include the four-axis on-board CAD system. All of EDM Network’s fast wire EDMs include on-site setup and training.

Related Content

-

Considerations for Mold Base Material Selection

Choosing the right material can greatly affect the profitability and cost of your application.

-

Advantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.