EDM

Integrated CAD/CAM Streamlines Electrode Manufacture, Improves Quality

A focus on electrode design and automation helps toolroom improve efficiency, reduce tooling costs and deliver higher quality products.

Read MoreSmall-Hole EDM With Automation for Moldmakers

IMTS2024: Belmont Equipment & Technologies offers its SY series high-speed CNC EDM drills for customizable, small-hole drills. These are useful in moldmaking for vent holes and ejector pin hole applications.

Read MoreEDM, Precision Milling, 3D Printing Improves Accuracy, Reduces Machining Time

IMTS 2024: MC Machinery Systems showcases an array of EDM and precision milling tools, as well as a wire laser metal 3D printer, all of which have the capacity to meet moldmaking needs.

Read MoreTechnology Review and Sourcing Guide 2024: EDM

Moldmakers rely on electrical discharge machining (EDM) routinely. EDM refers to wire, sinker and small-hole EDM. Access this exclusive, online-only content, including a suppliers list, EDM products, services and more.

Read MoreEDM Graphite Line for High-End EDM Machining

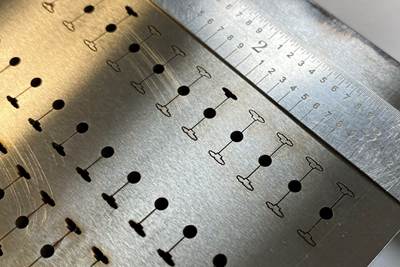

IMTS 2024: Mersen offers its complete family of EDM graphite, including its ultra-fine DS4 graphite. The graphite is used as the electrode which acts as a “cutting tool” in the sinker EDM, a machining process often used by moldmakers.

Read MoreQuality Tool & Die Enhances Performance With Advanced EDM and Milling Technologies

The adoption of Mitsubishi wire and sinker EDMs, along with the OPS Ingersoll five-axis milling machine with automated cells, has enabled unmanned operations and improved precision. As a result, QTD has expanded its facility, grown its workforce and increased its business by 10-15% annually.

Read MoreFour-Axis Fast Wire EDM Streamlines Mold Insert Removal

IMTS 2024: The four-axis Edmmax818W wire EDM from EDM Network offers a solution for simple 3D cutoffs to precision dies and tooling.

Read MoreHow to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreExtensive Evaluations Build The Plastek Group’s EDM Arsenal

Sinker and wire EDMs selected for speed, volumetric accuracy, surface finish, reliability, cost of ownership and extensive warranty.

Read MoreMachine Monitoring Platform Improves Machine Utilization, On-Time Delivery

Using data from a machine monitoring platform, Westminster Tool added almost 75 hours of capacity per week by shortening warmups and starting CNC and EDM machines sooner.

Read More